Powering Tomorrow: The Dawn of Superior EV Batteries

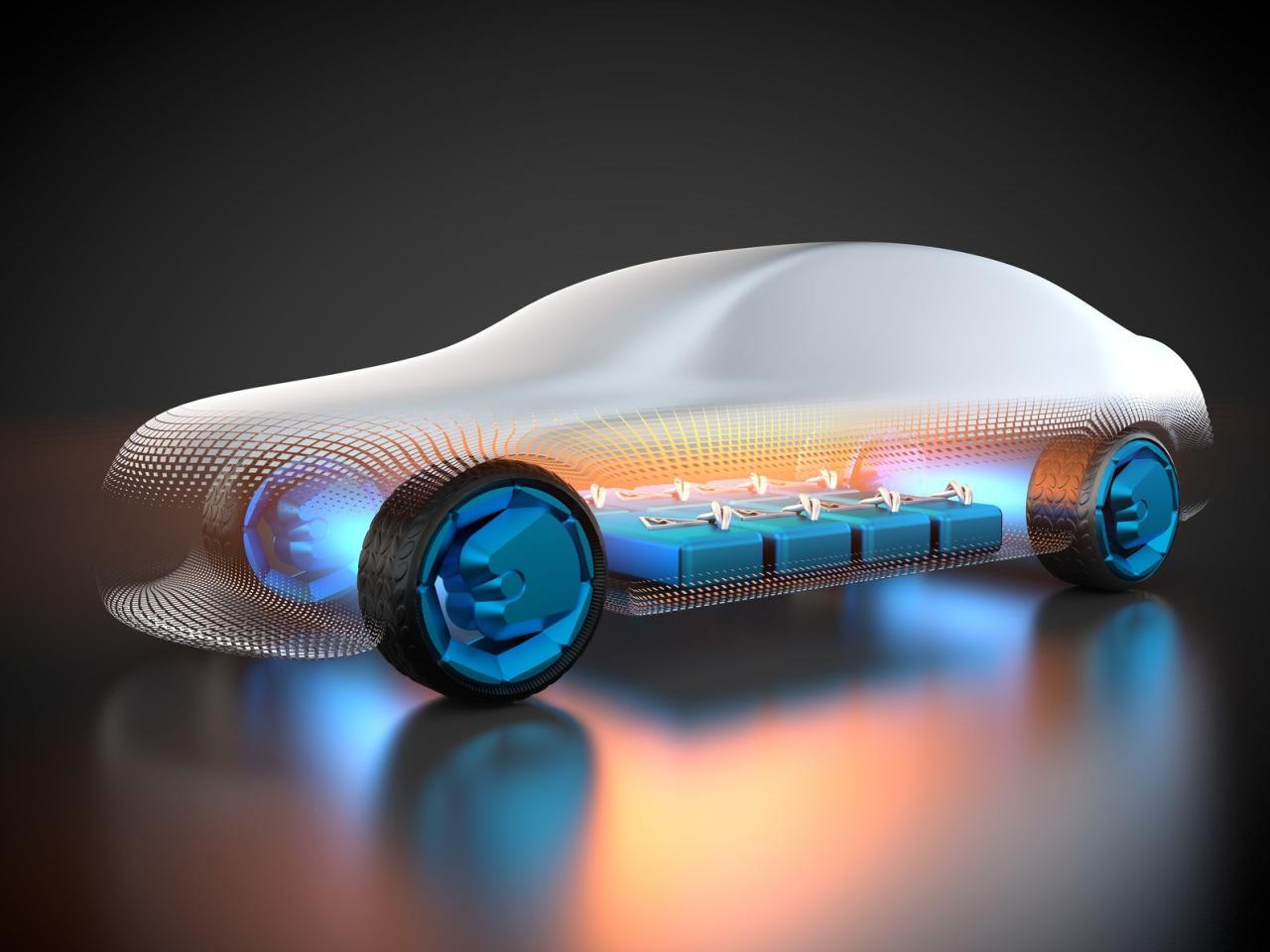

The electric vehicle (EV) revolution, once a nascent dream, is now unequivocally a global force reshaping the automotive landscape. At its very core, propelling this transformative shift is the rapid evolution of EV battery technology. Far more than mere power sources, these sophisticated energy storage systems are the critical enablers for extended range, faster charging, improved performance, and ultimately, widespread consumer adoption. For years, concerns about range anxiety, charging times, and battery longevity served as significant barriers. However, thanks to relentless innovation and massive investments in research and development, EV battery breakthroughs emerge with increasing frequency, promising to dismantle these challenges and unlock the full potential of sustainable transportation. These advancements are not just incremental; they represent fundamental shifts in materials science, engineering, and manufacturing that are set to redefine what’s possible for electric mobility.

The Lithium-Ion Legacy: A Foundation for Innovation

The story of modern EV batteries is largely rooted in the dominance of lithium-ion (Li-ion) technology. First commercialized in the early 1990s by Sony, Li-ion batteries quickly became the standard for portable electronics due to their high energy density and relatively low self-discharge rate. When electric vehicles began to gain traction in the early 21st century, Li-ion was the natural choice, scaling up from small consumer devices to power entire vehicles.

Early EV batteries faced significant limitations: they were expensive, heavy, offered limited range, and were slow to charge. They also raised concerns about thermal runaway and fire safety. However, continuous improvements have dramatically enhanced their performance. Researchers and engineers have tirelessly refined their chemistry, cell design, and packaging. Innovations in cathode materials (like Nickel-Manganese-Cobalt or NMC, and Nickel-Cobalt-Aluminum or NCA), anode materials (initially graphite), and electrolyte compositions have steadily boosted energy density, allowing for smaller, lighter battery packs that deliver greater range. Simultaneously, sophisticated Battery Management Systems (BMS) have become critical, overseeing charging, discharging, temperature control, and cell balancing to optimize performance, extend lifespan, and crucially, enhance safety. Despite newer technologies on the horizon, Li-ion remains the workhorse of the EV industry, with ongoing research continuing to refine its capabilities and address its inherent limitations. Its widespread production infrastructure also gives it a significant advantage in the short to medium term.

Pioneering the Next Generation: Emerging Battery Chemistries

While lithium-ion continues its evolution, the true excitement lies in the emerging battery chemistries poised to address its inherent limitations and unlock new levels of performance. These innovations aim for higher energy density, faster charging, greater safety, longer lifespan, and reduced reliance on critical minerals.

A. Solid-State Batteries (SSB): The Holy Grail. i. Fundamental Concept: Unlike traditional Li-ion batteries that use a liquid or gel electrolyte, solid-state batteries replace this with a solid material (e.g., solid polymer, sulfide, or oxide ceramics). This fundamental change has profound implications. ii. Key Advantages: The primary benefits are significantly higher energy density (potentially leading to double the range for the same size/weight), dramatically improved safety (eliminating flammable liquid electrolytes greatly reduces fire risk), and much faster charging capabilities (due to higher ion conductivity and stability). They also promise longer cycle life and potentially simpler battery pack designs without complex cooling systems. iii. Current Challenges: Despite their immense promise, SSBs face considerable challenges. Manufacturing at scale is difficult and expensive, achieving sufficient ion conductivity at practical temperatures remains a hurdle, and maintaining stable interfaces between the solid electrolyte and electrodes is complex. Large-scale commercialization is still several years away, with leading companies like Toyota, QuantumScape, and Solid Power investing heavily in overcoming these obstacles.

B. Lithium Iron Phosphate (LFP) Batteries: The Resurgence. i. Fundamental Concept: LFP batteries use lithium iron phosphate as the cathode material, in contrast to NMC or NCA chemistries. ii. Key Advantages: LFP batteries are inherently safer due to their stable chemistry, making them highly resistant to thermal runaway. They also boast a significantly longer cycle life (many thousands of charge cycles) and are considerably cheaper to produce as they avoid expensive and supply-constrained cobalt and nickel. This makes them ideal for entry-level and standard-range EVs, as well as commercial vehicles. iii. Current Status: Once seen as less energy-dense, recent advancements in cell-to-pack technology (e.g., BYD’s Blade Battery, CATL’s CTP) have improved their volumetric energy density, making them a compelling choice. Tesla, BYD, and other major manufacturers are increasingly adopting LFP for their standard-range models, especially in markets like China, driving down EV costs and improving accessibility.

C. Sodium-Ion (Na-ion) Batteries: A Resourceful Alternative. i. Fundamental Concept: Na-ion batteries replace lithium with sodium, a far more abundant and cheaper element. They operate on a similar principle to Li-ion but use different electrode materials suitable for sodium ions. ii. Key Advantages: The most significant benefit is the vast abundance and low cost of sodium, which is readily available globally. This offers superior supply chain security and reduces reliance on geopolitically sensitive lithium. Na-ion batteries also perform well in cold weather and have good safety characteristics. iii. Current Challenges: Currently, Na-ion batteries have lower energy density compared to Li-ion, making them less suitable for long-range, high-performance EVs. They are, however, promising for stationary energy storage, two-wheelers, and potentially for more affordable, shorter-range urban EVs. Companies like CATL are actively developing and commercializing Na-ion technology, with first applications expected within the next few years.

D. Silicon Anodes: Boosting Li-ion Performance. i. Fundamental Concept: Current Li-ion batteries typically use graphite as the anode material. Silicon, however, can store significantly more lithium ions per unit volume, offering a much higher theoretical capacity. ii. Key Advantages: Integrating silicon into the anode can dramatically increase the energy density of existing Li-ion batteries (up to 20-40% improvement), leading to greater range without increasing battery pack size. It also holds potential for faster charging rates. iii. Current Challenges: Silicon undergoes significant volume changes (up to 400%) during charging and discharging, which can lead to material degradation and reduced battery life. Researchers are working on nano-structured silicon, silicon-carbon composites, and other engineering solutions to mitigate this swelling and improve cycle stability. Companies like StoreDot, Sila Nanotechnologies, and various automakers are actively pursuing this path.

E. Lithium-Sulfur (Li-S) Batteries: High Energy, Lower Cost. i. Fundamental Concept: Li-S batteries use a lithium metal anode and a sulfur cathode. Sulfur is abundant and inexpensive. ii. Key Advantages: They offer a very high theoretical energy density, potentially 2-3 times that of current Li-ion batteries, making them highly attractive for applications requiring ultra-long range. They also avoid expensive and rare cathode materials like cobalt and nickel. iii. Current Challenges: The main hurdles for Li-S batteries include their relatively short cycle life (due to the “polysulfide shuttle” effect and lithium dendrite formation) and degradation of the sulfur cathode. Significant research is ongoing to improve their stability and commercial viability.

Beyond Chemistry: Innovations in Battery Design and Manufacturing

Breakthroughs in EV batteries are not solely about new chemical compositions. Innovations in how cells are designed, how packs are assembled, and how they are manufactured also play a crucial role in enhancing performance, reducing costs, and improving safety.

A. Cell-to-Pack (CTP) Technology: i. Fundamental Concept: Traditionally, battery packs are made from individual cells grouped into modules, which are then assembled into the final pack. CTP technology eliminates the module layer, directly integrating cells into the battery pack structure. ii. Key Advantages: This design significantly increases volumetric energy density (more cells in the same space), reduces weight (fewer non-active components), lowers manufacturing complexity and cost, and improves thermal management. iii. Impact: Pioneered by companies like BYD (Blade Battery) and CATL, CTP technology allows for more compact and efficient battery packs, contributing to greater vehicle range and interior space.

B. Structural Battery Packs: i. Fundamental Concept: Taking CTP a step further, structural battery packs integrate the battery directly into the vehicle’s chassis, making the battery itself a structural component of the car. ii. Key Advantages: This approach further reduces weight, simplifies manufacturing processes, improves torsional rigidity of the vehicle, and frees up interior space. It also potentially offers better crash protection by distributing impact forces. iii. Impact: Tesla’s 4680 battery cell and its integration into a structural pack design is a prominent example. This innovation aims to reduce vehicle complexity and cost, while enhancing safety and performance.

C. Dry Electrode Manufacturing: i. Fundamental Concept: Traditional battery electrode manufacturing uses energy-intensive wet processes, involving solvents that need to be dried and recycled. Dry electrode manufacturing eliminates the use of these solvents, instead using dry binders and mechanical processes. ii. Key Advantages: This method significantly reduces energy consumption and carbon emissions during manufacturing, lowers production costs, and could potentially enable faster production lines. iii. Impact: Pioneered by companies like Tesla (for its 4680 cells) and others, dry electrode manufacturing represents a significant step towards more sustainable and cost-effective battery production.

D. Fast Charging Technologies: i. Fundamental Concept: Beyond just energy density, the speed at which an EV can recharge is critical for consumer convenience. Fast charging technologies involve optimizing cell chemistry, electrode design, and cooling systems to handle high power inputs without degradation or overheating. ii. Key Innovations: This includes advanced Battery Management Systems (BMS) that precisely control the charging curve, pre-conditioning systems that bring the battery to an optimal temperature for rapid charging, and new anode materials (like silicon-carbon composites or niobium-based oxides) that can accept charge much faster. iii. Impact: Advances promise to reduce charging times from hours to minutes, approaching the refueling speed of gasoline cars. Companies like StoreDot (with their XFC technology aiming for “5 minutes to 100 miles of range”) and Porsche (with its 800V architecture in the Taycan) are leading this charge.

The Broader Ecosystem: Battery Recycling, Second Life, and Sustainability

The journey of an EV battery doesn’t end when it’s manufactured or even when it reaches the end of its automotive life. A holistic approach to battery technology encompasses its entire lifecycle, with sustainability becoming a paramount concern.

A. Battery Recycling: i. Need for Recycling: As millions of EVs enter circulation, effective recycling infrastructure becomes crucial to recover valuable raw materials (lithium, cobalt, nickel, manganese, copper) and prevent environmental pollution. It reduces reliance on new mining and mitigates supply chain risks. ii. Technologies: Various recycling methods exist, including pyrometallurgy (high-temperature smelting) and hydrometallurgy (chemical leaching). Hydrometallurgy is generally preferred for its higher recovery rates of specific materials and lower energy consumption. iii. Industry Initiatives: Major battery manufacturers and automakers are investing in recycling partnerships and developing closed-loop systems to reintroduce recycled materials back into new battery production, creating a more circular economy.

B. Second-Life Applications: i. Extending Utility: An EV battery might no longer be suitable for automotive use once its capacity drops below 70-80% of its original state, but it still holds significant energy storage potential. ii. Stationary Storage: These “second-life” batteries can be repurposed for less demanding applications like stationary energy storage (e.g., buffering renewable energy from solar or wind farms, powering homes or businesses, or providing grid stability services). This extends the battery’s useful lifespan, reduces waste, and offers an affordable energy storage solution. iii. Benefits: This approach maximizes the value of the battery’s embedded energy and materials, delays recycling, and provides sustainable solutions for renewable energy integration.

C. Ethical Sourcing and Sustainable Materials: i. Addressing Concerns: The rapid growth of EVs has raised concerns about the ethical sourcing of raw materials, particularly cobalt (associated with artisanal mining practices and child labor) and lithium. ii. Industry Response: Automakers and battery manufacturers are increasingly focusing on supply chain transparency, responsible mining initiatives, and developing chemistries that reduce or eliminate the need for controversial materials (e.g., LFP batteries, which are cobalt-free). iii. Innovation in Alternatives: Research into alternative materials and novel production methods that are less resource-intensive and more environmentally friendly is a continuous area of focus.

The Impact of Battery Breakthroughs: Shaping the Future of Mobility

The pace of battery innovation is accelerating, and its impact on the automotive industry and beyond is profound and multifaceted.

A. Democratization of EVs: As battery energy density increases and costs continue to fall (driven by breakthroughs and economies of scale), EVs will become more affordable and accessible to a broader consumer base, accelerating the transition away from internal combustion engines. B. Unlocking New Vehicle Segments: Longer range and faster charging capabilities will enable the widespread adoption of electric trucks, buses, and potentially even electric aviation, opening up entirely new segments for electrification. C. Grid Integration and Energy Security: Advanced batteries, particularly with vehicle-to-grid (V2G) capabilities, will allow EVs to become active participants in the energy grid, storing renewable energy and feeding power back during peak demand. This enhances grid stability and energy independence. D. Performance Redefined: Instantaneous torque delivery from electric motors, combined with lighter, more energy-dense batteries, will continue to push the boundaries of vehicle performance, not just in terms of acceleration but also handling and dynamics. E. Sustainable Future: Ultimately, breakthroughs in EV battery technology are critical for realizing a sustainable transportation future, significantly reducing global carbon emissions and mitigating climate change.

The journey of the EV battery is far from over. Each breakthrough, whether in chemistry, design, or manufacturing, builds upon the last, pushing the industry closer to a future where electric vehicles are not just an alternative, but the dominant, superior form of personal and commercial transportation. The quiet hum of an electric motor, powered by these ever-evolving wonders of engineering, signals a cleaner, more efficient, and more exhilarating tomorrow on our roads.