The pursuit of automotive excellence has shifted its primary focus from raw engine displacement to the sophisticated science of air management. In the modern era of vehicle development, aerodynamic engineering stands as the most critical factor in determining the efficiency and performance of next-generation transport. As the global automotive industry moves toward total electrification, every fraction of wind resistance becomes a barrier to extended battery range.

Designers are no longer just creating beautiful silhouettes; they are sculpting surfaces that minimize turbulence and optimize high-speed stability. The air flowing over a vehicle at highway speeds acts as an invisible wall that the machine must pierce with minimal effort. Mastering this interaction requires a deep understanding of fluid dynamics, thermal management, and structural acoustics. It is a delicate balance where aesthetic appeal must meet the rigid demands of physics to create a truly revolutionary driving experience.

This comprehensive exploration will delve into the technical breakthroughs that allow vehicles to glide through the atmosphere with unprecedented ease. We will examine how active systems, underbody management, and new material sciences are coming together to redefine the look and feel of the cars we drive.

The Fundamental Physics of Automotive Drag

To understand modern design, we must first look at the invisible forces that fight against a vehicle’s forward motion. Drag is the primary enemy of efficiency and high-speed performance in any ground vehicle.

A. Understanding the Coefficient of Drag ($C_d$)

The $C_d$ is a dimensionless value used to quantify the resistance of an object in a fluid environment. A lower number means the car is “slippery” and can maintain speed with less energy consumption.

B. The Impact of Frontal Area on Resistance

Total air resistance is not just about shape but also the size of the “hole” a car punches through the air. Reducing the frontal area while maintaining cabin space is a major challenge for contemporary engineers.

C. Skin Friction vs. Form Drag

Skin friction is the air “sticking” to the car’s paint, while form drag is caused by the overall shape. Most automotive breakthroughs focus on form drag because it accounts for the majority of resistance at high speeds.

Managing Airflow Over the Vehicle Body

The top surfaces of a car are where most people notice aerodynamic styling, but the science goes far beyond a simple curved roofline. Every pillar and mirror must be optimized for the wind.

A. The Importance of A-Pillar and Mirror Design

Side mirrors are often the biggest culprits for creating “dirty” air and wind noise. Next-generation vehicles are increasingly using cameras to replace bulky mirrors, drastically reducing turbulence.

B. Optimizing the “Tear-Drop” Silhouette

Nature’s most aerodynamic shape is the teardrop, which tapers gently toward the rear. Modern sedans use long, sloping rear decks to ensure air reconnects smoothly behind the vehicle.

C. Roof Spoilers and Vortex Generators

Small fins on the roof or rear edges can help “clean up” the air before it leaves the car. This prevents a large vacuum of low pressure from forming behind the vehicle, which would otherwise pull it backward.

The Hidden Science of Underbody Management

The bottom of a car is often neglected, but it is actually where some of the most significant aerodynamic gains are made. A flat underbody is essential for high-efficiency travel.

A. Full Underbody Paneling and Smoothing

Traditional cars have exposed exhaust pipes and suspension parts that create massive turbulence. Next-generation EVs use flat protective plates to turn the underside into a smooth “skate” for the air.

B. The Role of the Rear Diffuser

A diffuser at the back of the car helps expand the air coming from underneath, accelerating it and creating a low-pressure zone. This “sucks” the car to the road, improving grip without adding heavy wings.

C. Wheel Well Management and Air Curtains

Spinning wheels create a chaotic mess of air that spills out the sides. Air curtains are specialized vents in the front bumper that blow a “sheet” of air over the wheels to seal off this turbulence.

Active Aerodynamic Systems

Static shapes are limited because a car needs different properties at 30 mph than it does at 80 mph. Active systems allow the car to change its shape in real-time.

A. Active Grille Shutters for Thermal Control

Radiators need air for cooling, but open grilles create drag. Active shutters close the grille when the engine is cool, forcing air around the car instead of through the messy engine bay.

B. Deployable Spoilers and Speed-Sensitive Wings

Some performance cars feature wings that only emerge at high speeds. These systems provide downforce for cornering but hide away during cruising to maximize fuel economy.

C. Active Ride Height and Suspension Tuning

Lowering the car at highway speeds reduces the amount of air that flows underneath. This improves stability and decreases the frontal area, making the vehicle much more efficient on long trips.

Thermal Management and Cooling Integration

Aerodynamics isn’t just about moving the car; it’s also about moving heat. Engineering the flow of air into and out of the cooling system is a vital part of design.

A. Ducting for Brake Cooling and Efficiency

High-performance driving creates massive heat in the brakes. Engineers design “S-ducts” that channel air to the wheels without increasing the overall drag of the vehicle’s nose.

B. Battery Thermal Regulation in Electric Vehicles

EVs require precise temperature control for their battery packs. Aerodynamicists work with battery engineers to use ambient airflow to cool the cells while minimizing wind resistance.

C. Internal Airflow for Cabin Comfort

The air that enters the cabin for the AC system also contributes to drag. Advanced intake designs ensure the cabin stays pressurized and fresh without creating a “parachute” effect at the vents.

The Impact of Wheel and Tire Design

Wheels are one of the most difficult parts of a car to optimize because they are constantly rotating. The design of the rim can change a car’s range by several percentage points.

A. Aero-Wheels and Closed-Face Rims

Many modern electric cars use flat, solid-looking wheels. This prevents air from getting “caught” in the spokes, which significantly reduces drag during highway cruising.

B. Tire Sidewall Smoothing and Lettering

Even the raised lettering on a tire’s sidewall can create micro-turbulence. Next-generation tires feature smooth sidewalls to allow air to pass over them as cleanly as possible.

C. Narrow Section Widths for Reduced Drag

Narrower tires have a smaller frontal area, which is better for aero. Engineers must balance this with the need for a wide “contact patch” to maintain safety and cornering grip.

Computational Fluid Dynamics (CFD) in Design

Before a single physical model is built, engineers spend thousands of hours in virtual wind tunnels. This software allows for rapid iteration of complex shapes.

A. Simulating Airflow at the Molecular Level

CFD software can track millions of “virtual air particles” as they interact with the car’s body. This reveals hidden “hotspots” of turbulence that a physical wind tunnel might miss.

B. Iterative Design Through Machine Learning

Computers can now suggest subtle changes to a fender or hood to improve efficiency. This “generative design” often results in organic shapes that a human designer might never consider.

C. Digital Wind Tunnels vs. Physical Testing

While CFD is powerful, the final validation still happens in a physical wind tunnel with smoke and laser sensors. The combination of both ensures the highest level of aerodynamic precision.

Materials Science and Aerodynamic Efficiency

The materials used to build the car’s skin have a direct impact on how it handles the air. New composites are allowing for shapes that were previously impossible to manufacture.

A. Carbon Fiber and Complex Curvatures

Carbon fiber allows for extremely sharp edges and deep curves that stay rigid under wind pressure. This helps maintain the aerodynamic “integrity” of the shape at very high speeds.

B. Self-Cleaning and Hydrophobic Coatings

A car covered in dirt is less aerodynamic than a clean one. New paint technologies help shed water and debris, ensuring the surface stays smooth throughout a long drive.

C. Flexing Body Panels for Variable Geometry

Future designs may feature “shape-shifting” materials that bend slightly at different speeds. This would allow a car to physically morph into a more aerodynamic version of itself.

The Aero-Acoustics of Modern Vehicles

Wind noise is one of the primary complaints in high-end luxury vehicles. As engines get quieter (especially in EVs), the sound of the wind becomes much more noticeable.

A. Eliminating Wind Whistle and Buffeting

Small gaps between body panels can create annoying whistles. Aerodynamicists use “hemmed” edges and tight tolerances to ensure air flows silently over every seam.

B. The Science of Acoustic Glass and Sealing

Double-pane glass and specialized door seals help block out the noise created by high-speed air. This creates a “serene” cabin environment that is essential for a premium experience.

C. Designing Quiet Pillars and Roof Rails

Even the shape of the rain gutters on the roof is optimized for sound. By managing the “wake” created by these parts, engineers can prevent the “thrumming” sound heard at high speeds.

Aerodynamics for Commercial Transport and Trucks

While consumer cars get the most attention, the biggest efficiency gains are happening in the world of heavy trucking. Aerodynamic kits are transforming the logistics industry.

A. Trailer Tails and Side Skirts

Adding simple flaps to the back of a trailer can reduce fuel consumption by up to 5%. Side skirts prevent air from getting trapped under the trailer where the messy wheels and axles are located.

B. Platooning and Slipstreaming Technology

Advanced sensors allow trucks to follow each other very closely in a “platoon.” The lead truck punches a hole in the air, allowing the following trucks to use significantly less energy.

C. Cabin Integration and Gap Fairings

Closing the gap between the truck cab and the trailer prevents a massive “drag pocket.” Seamless integration is the future of sustainable long-haul freight.

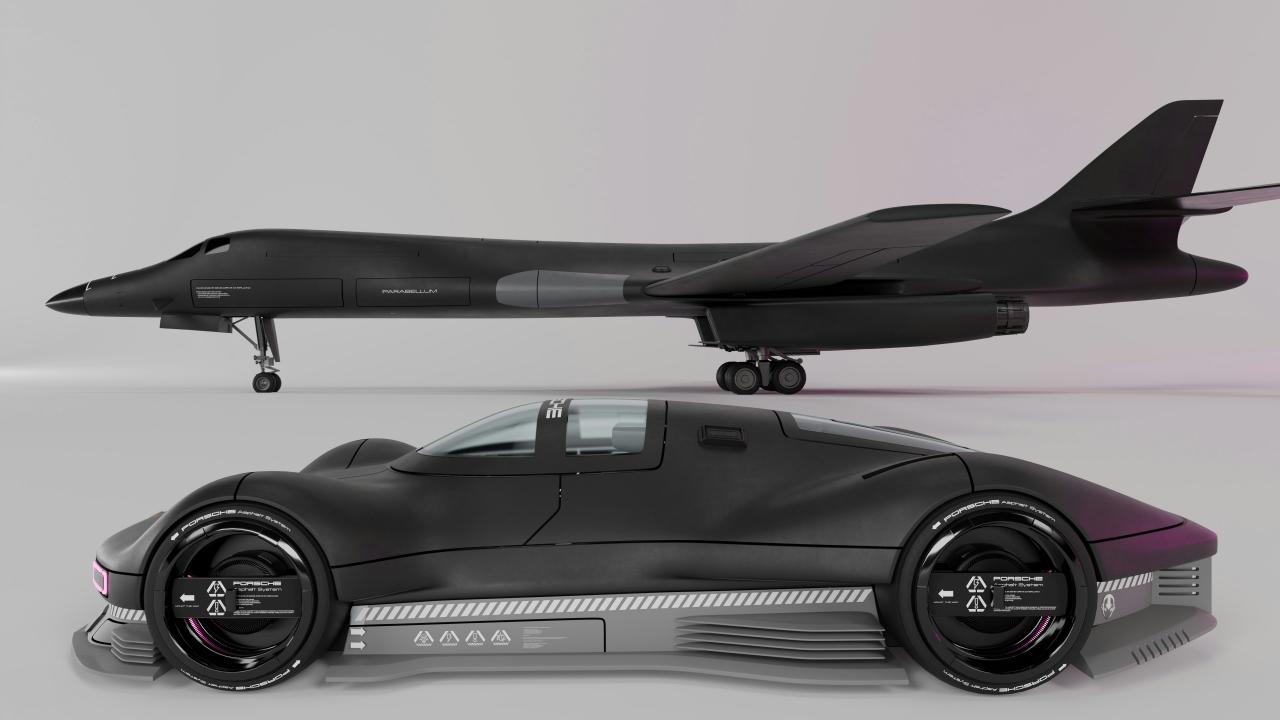

The Future of High-Speed Ground Travel

As we look toward the future, the lines between automotive design and aerospace engineering are becoming increasingly blurred.

A. Ground Effect Vehicles and Hyper-Efficiency

Some future concepts use “ground effect” to reduce drag to near-zero levels. This involves carefully managing the air under the car to lift it slightly off the suspension.

B. Integration with Urban Infrastructure

The way air flows between buildings in a city affects a car’s performance. Future “smart cities” may be designed to complement the aerodynamics of the vehicles traveling through them.

C. The Aesthetics of Pure Efficiency

We are moving toward a new “design language” where the wind dictates the look of the car. This leads to sleek, minimalist designs that prioritize function over traditional styling cues.

Conclusion

Aerodynamic engineering is the silent force that will define the future of the automotive industry. The transition to electric mobility has made the pursuit of a low drag coefficient more important than ever before. Every curve on a modern vehicle is a deliberate choice made to balance beauty with the harsh laws of fluid dynamics. Hidden areas like the underbody and wheel wells hold the key to the next major leap in vehicle range. Active systems allow a car to be a “chameleon” that adapts its shape to the specific speed of the moment.

Computational tools have accelerated our ability to find the perfect balance between lift, drag, and downforce. Sustainability in transport is not just about the fuel we use but how efficiently we move through the air. Wind noise management is becoming a critical pillar of luxury as electric motors remove engine sounds. Next-generation materials will allow for “living” car bodies that can morph and change with the wind. The collaboration between aerodynamicists and stylists is creating a new era of high-performance art.

Heavy industry is finally embracing air management to lower the carbon footprint of global logistics. Data-driven design is replacing the “gut feeling” of traditional clay modeling in the studio. The vehicles of tomorrow will look like nothing we have seen before because the wind demands it. Efficiency gains from better aero are often “free” because they don’t require expensive battery upgrades. Mastering the air is the ultimate challenge for the next generation of automotive designers and engineers. Explore the world of aerodynamics today to understand why the cars of the future look the way they do.